Your contact person

Ottmar Kuster Sales DE-Southwest

Transfer systems

Modular. Movable. Productive.

The transfer and logistics systems from KARL set standards for an optimised material flow in production.

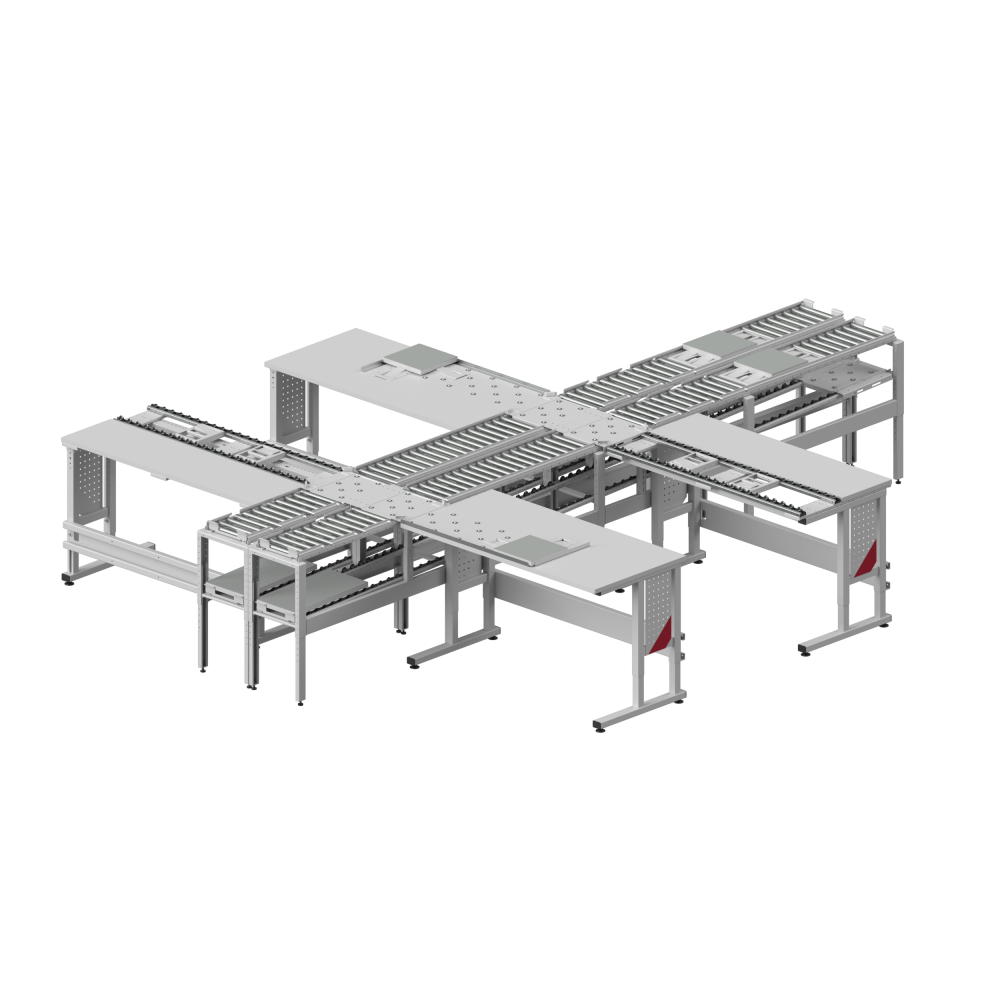

Modular.

The modular structure of the KARL transfer systems offers almost unlimited customisation and expansion options.

Whether straight transfer lines or complex systems with multiple levels and automated processes - the systems can be customised precisely to the requirements of any production environment. Thanks to the modular system, individual components can be added or replaced quickly so that the transfer system can be adapted to changing production requirements at any time.

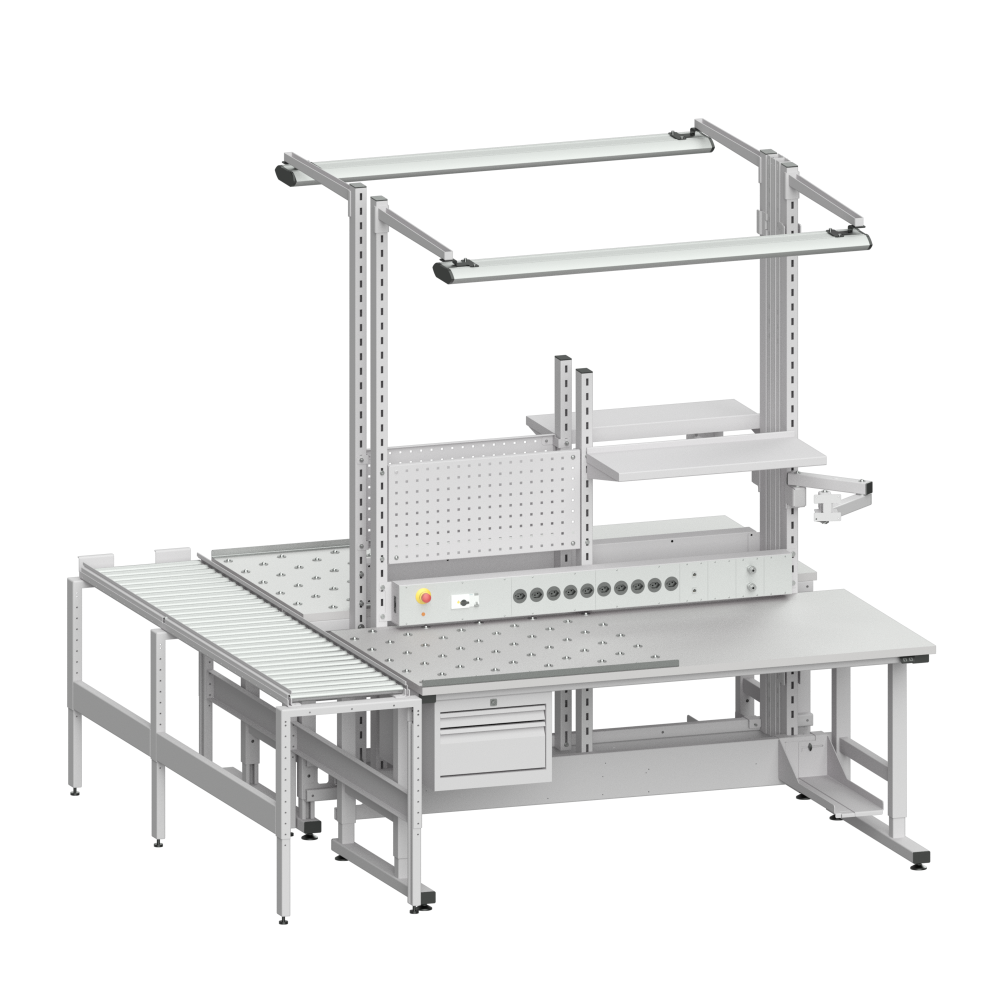

Movable.

Thanks to their moving elements, KARL transfer systems ensure a smooth material flow, whether in assembly, order picking or transport.

Roller conveyors and roller rails enable continuous and uninterrupted transport of workpiece carriers or transport containers, while ergonomically designed work tables with material buffering increase productivity. This manoeuvrability reduces downtimes and ensures that the material flow remains uninterrupted.

Productive.

The KARL transfer systems make a significant contribution to increasing productivity by making the material flow more efficient.

The clear separation of transport and work areas prevents mutual interference and saves valuable time. The integration of functions such as diverters, workpiece carrier return and flow racks optimises the entire production process and minimises waste. The result is a well thought-out system that promotes productivity at all levels.

Possible applications

Mehr erfahren

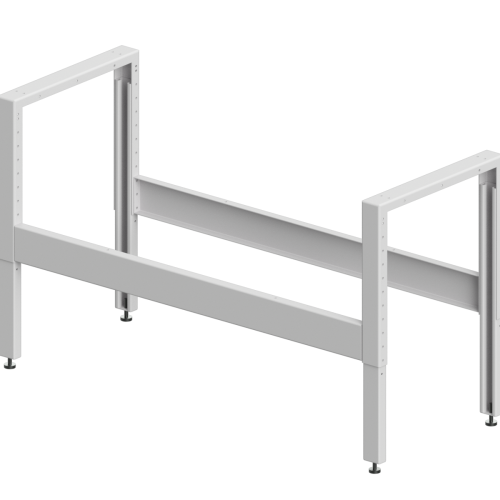

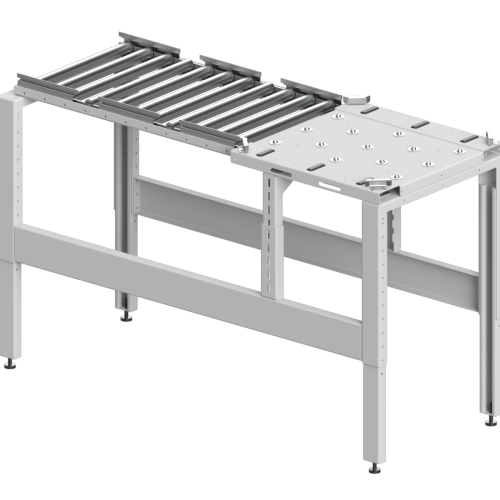

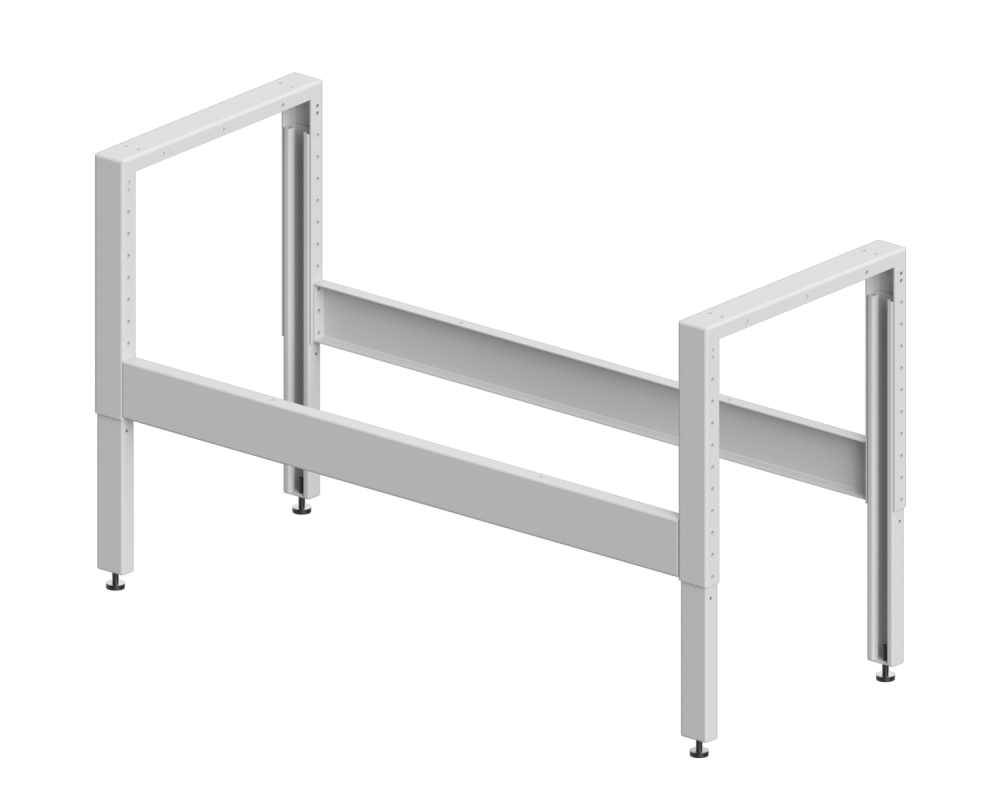

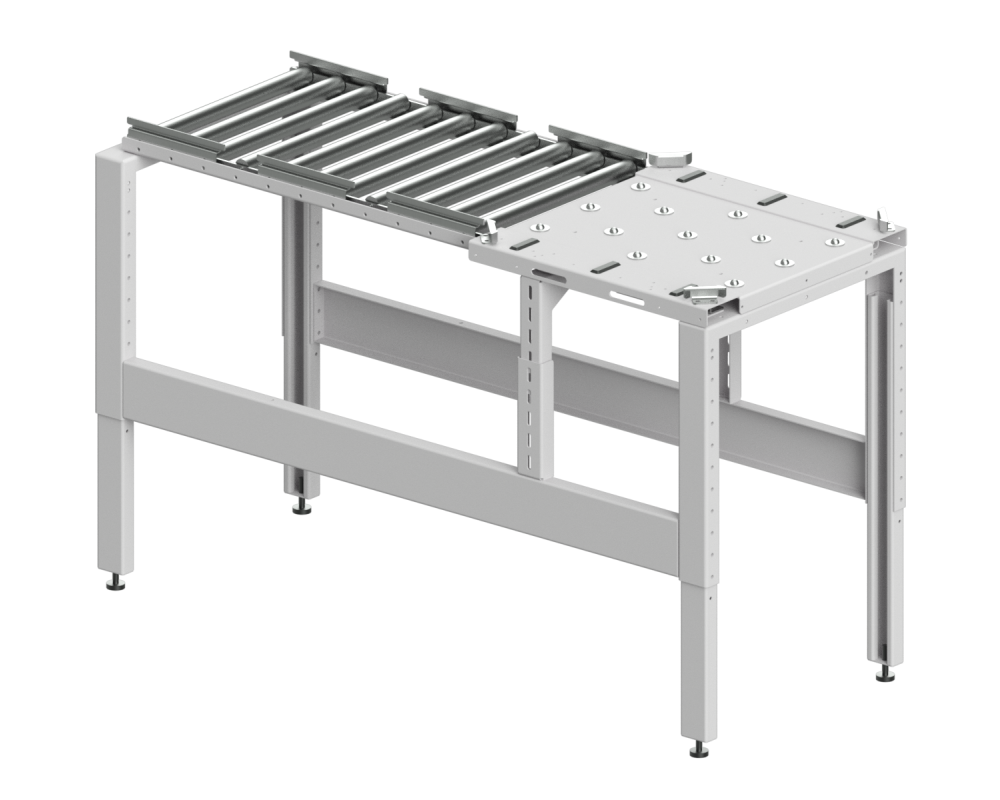

Transfer racks

- Mounting of roller and roller tracks

- Frame made of sheet steel, conductive powder-coated

- Infinitely height-adjustable from 680-980 mm

- Load capacity: 120 kg / level

- Height levelling elements in the foot section;

- Discharge elements can be fitted to connect tables

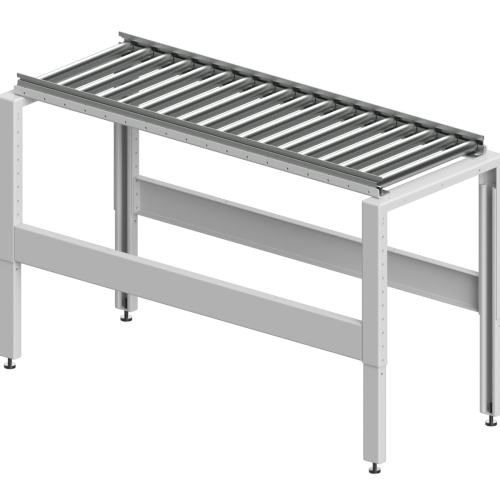

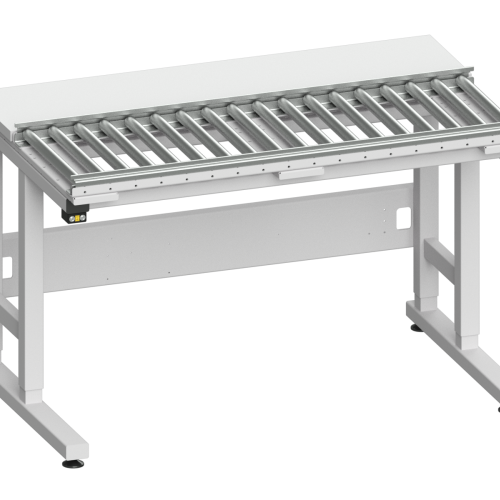

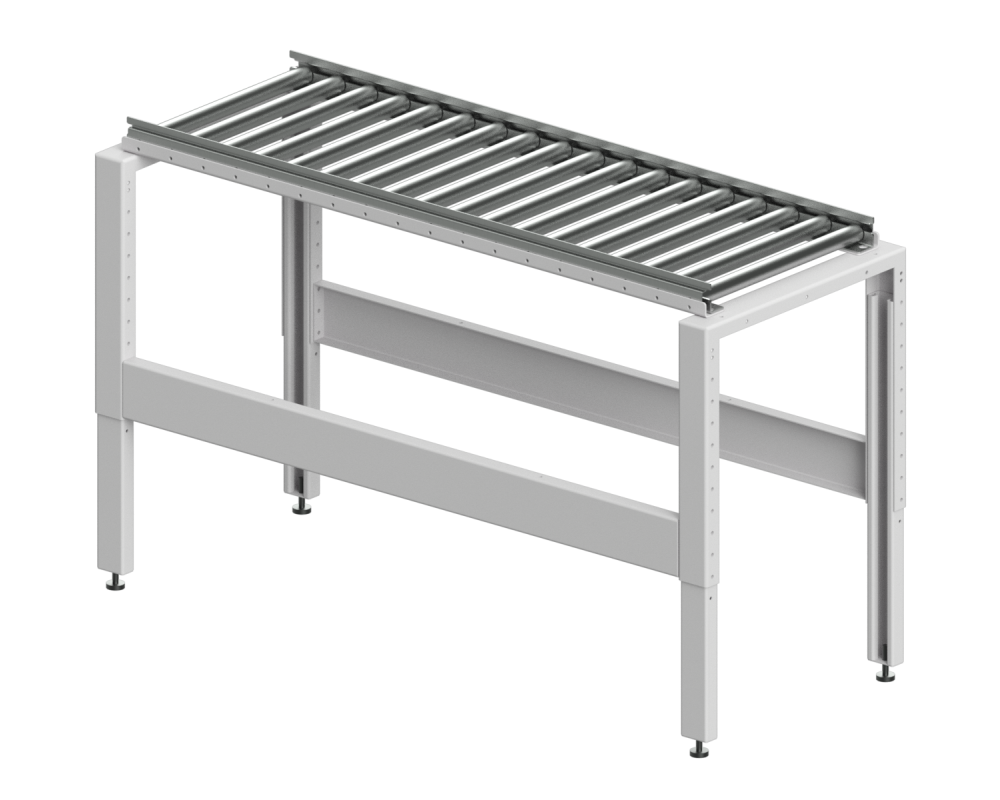

Roller conveyor

- Angled rails with chromatised steel castors for mounting on the transfer frame

- Rollers ⌀ 30 mm

- Roller pitch: 136 mm (optional: 68 mm)

- Load capacity: 100 kg / running metre.

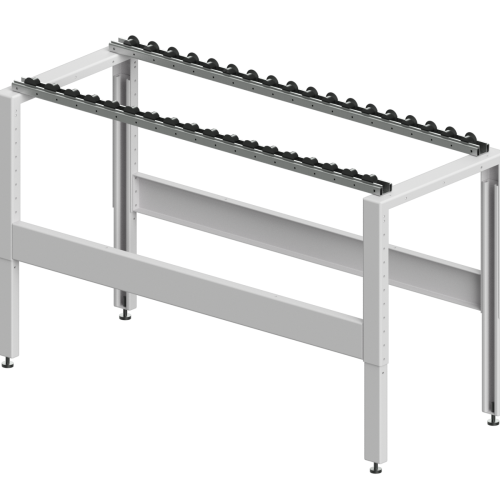

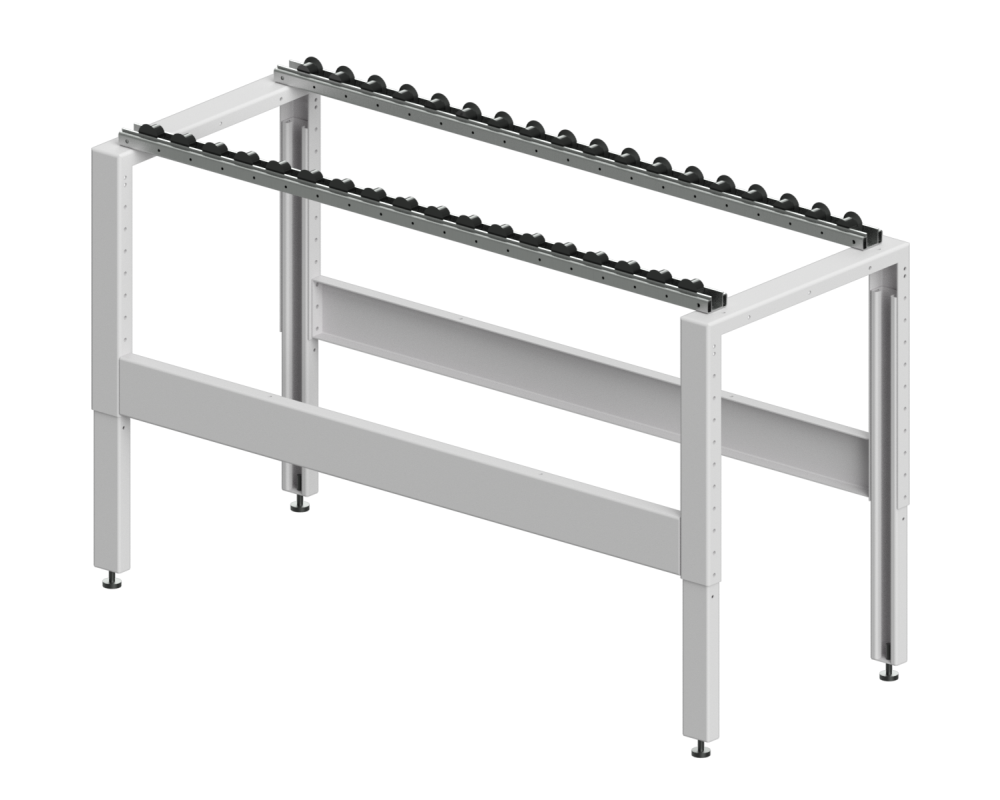

Roller mouldings

- Support rails with integrated plastic flanged rollers for mounting on the transfer frame

- Roller diameter: 28 mm, flange diameter: 41 mm

- Roller grid: 66 mm

- Load capacity: 100 kg / running metre

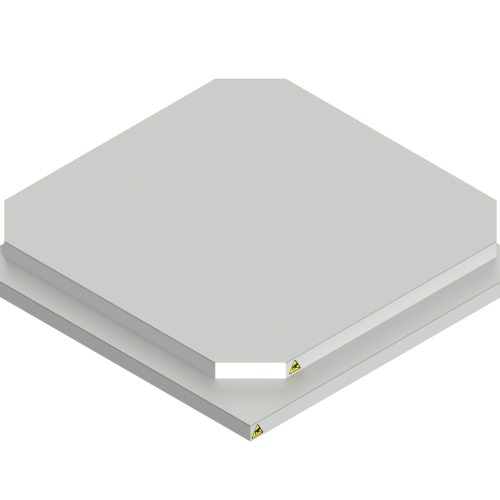

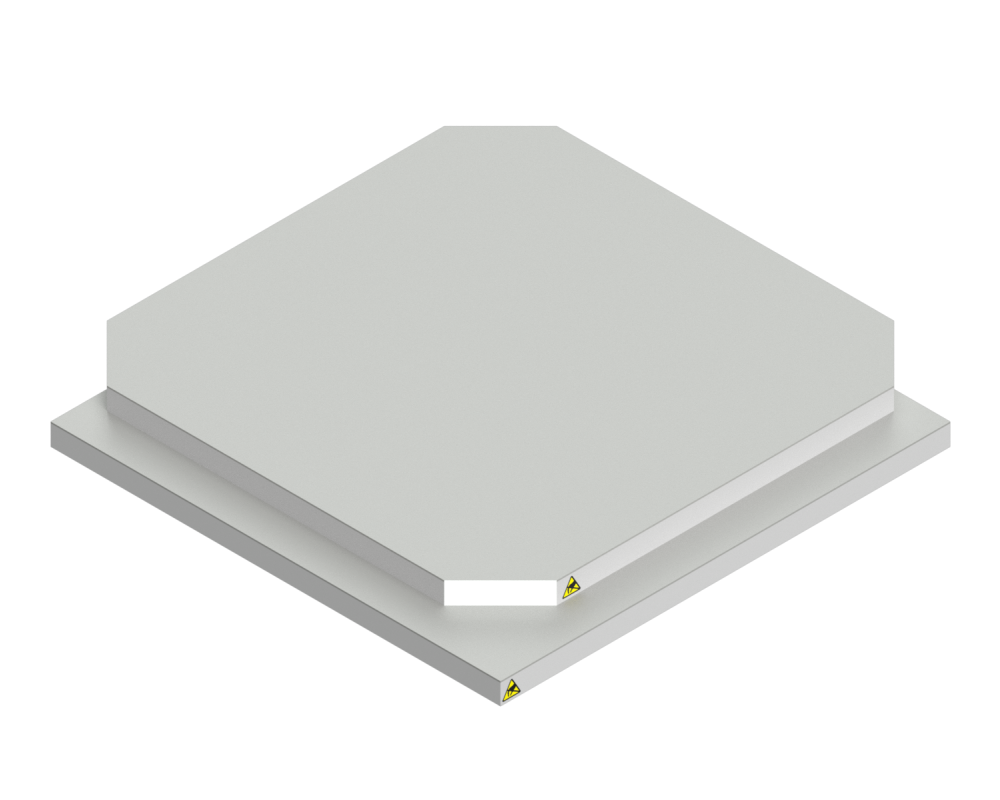

Workpiece carrier

- Top side with non-slip rubber coating

- Underside with robust hard laminate covering

- with resistant edging

- Thickness: 27 mm

Ball ejection elements

- for the ejection of workpiece carriers

- Support element made of sheet steel for placing on the roller conveyor / roller tracks

- Infinitely variable for roller tracks, adjustable in 250 mm increments for roller tracks

- inserted ball elements with chromatised steel ball, ⌀ 15 mm

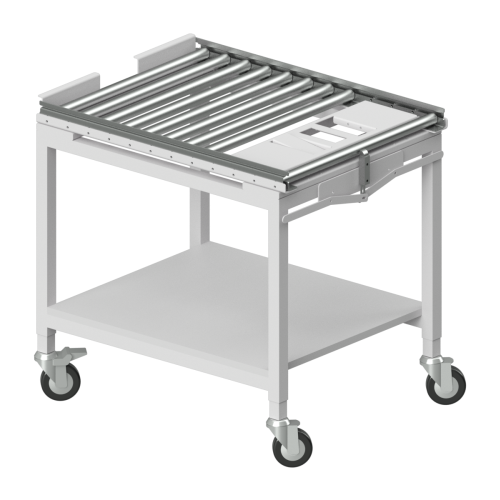

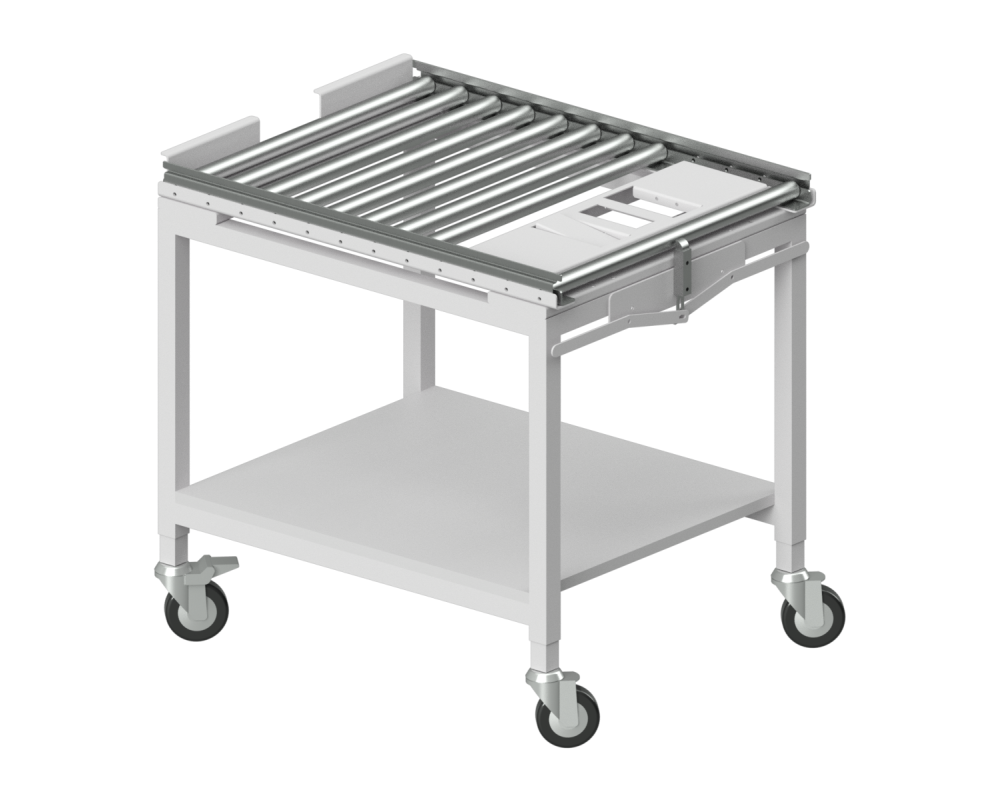

TRANSFER transport trolley

- Side trolley made of square tubular steel with 4 swivel castors

- Attached roller rails or roller conveyor with clamping element for fixing a workpiece carrier

- Docking system for fixing to the roller conveyor or roller tracks

- Docking with automatic locking, release with one hand movement

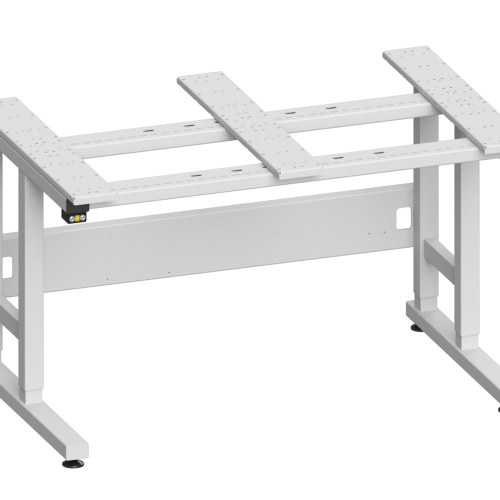

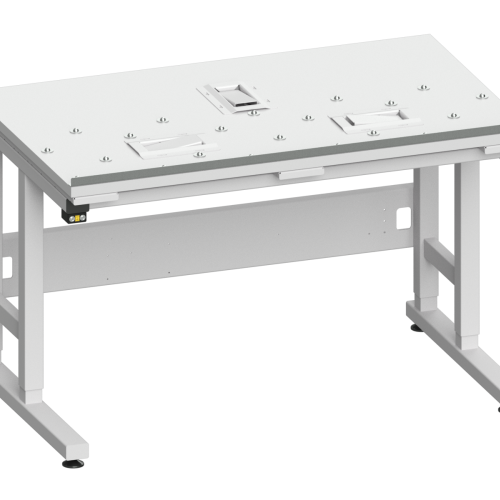

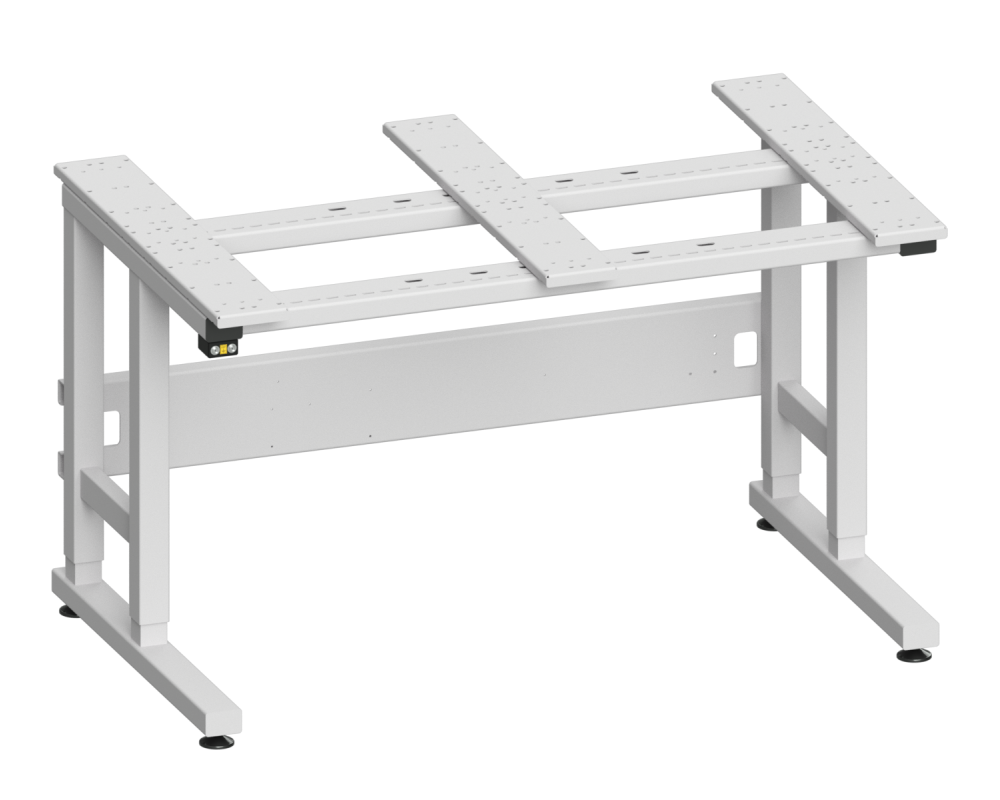

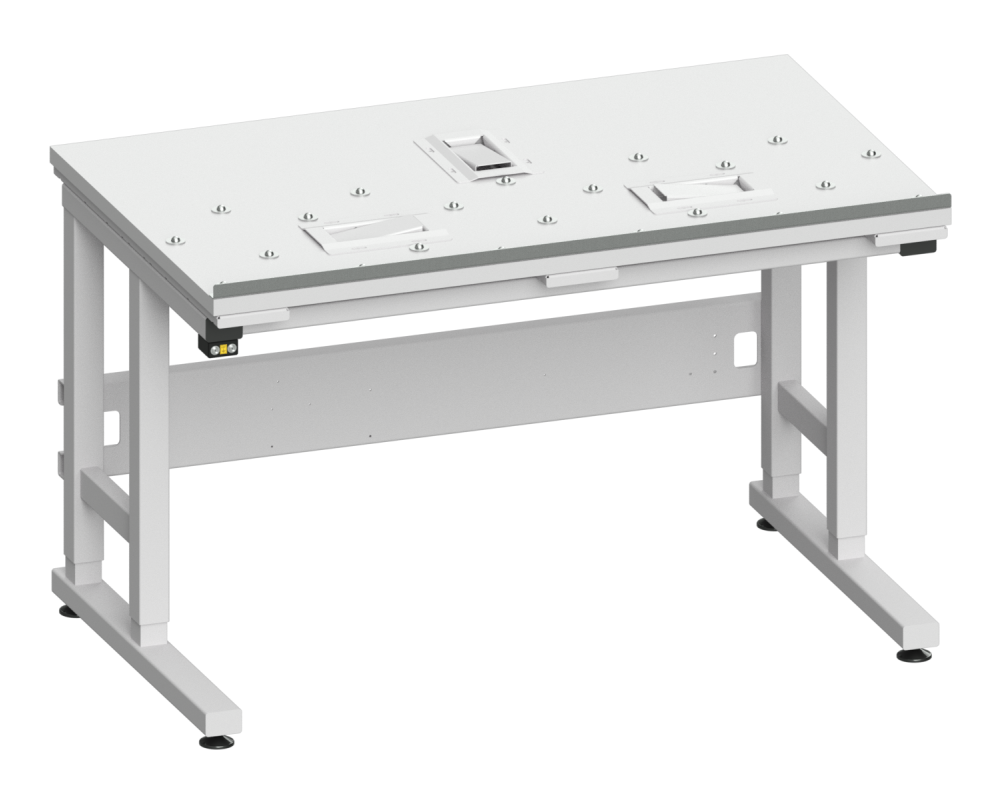

SINTRO transfer rack

- Height adjustment from 740 to 1140 mm

- Stepless height adjustment with clamping screws

- Cross strut for attaching a footrest

- Work surface can be loaded with 200 kg uniform surface load

- Height levelling elements in the foot section

- All metal parts powder-coated

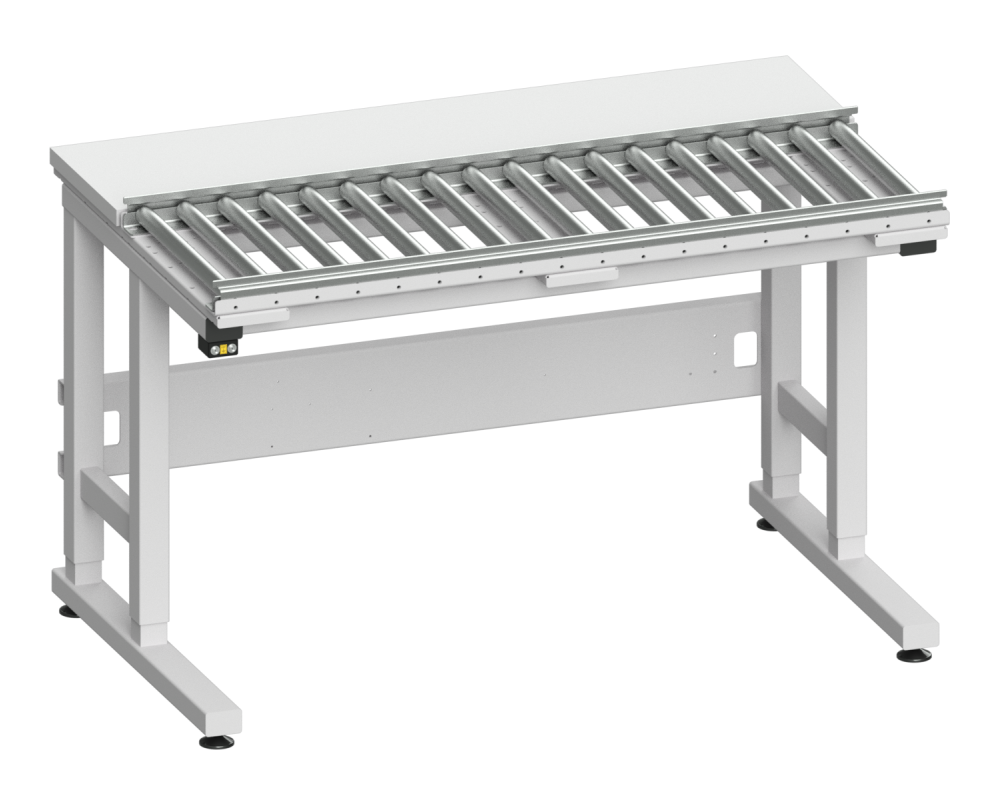

SINTRO roller conveyor

- Angled rails with chromatised steel castors

- for mounting on the SINTRO table frame

- Rollers Ø 30 mm

- Roller pitch: 136 mm, optional: 68 mm

- Load capacity: 100 kg / running metre.

Spherical table tops

- for turning the workpiece or workpiece carrier at the workstation

- Light grey worktop with hard-wearing edging

- Inserted ball elements with chromatised steel ball, ⌀ 15 mm

- Workpiece carrier can be rotated and fixed in 90° steps

- Integrated clamping elements for fixing the workpiece carrier

DE

DE