Your contact person

Ottmar Kuster Sales DE-Southwest

Kistler Group

At Kistler Instrumente AG

in Sindelfingen the focus is on

ergonomics and flexibility

Kistler is the global market leader in dynamic measurement technology and offers customised solutions for industry and research, from sensors to the cloud.

https://www.kistler.com/DE/de/

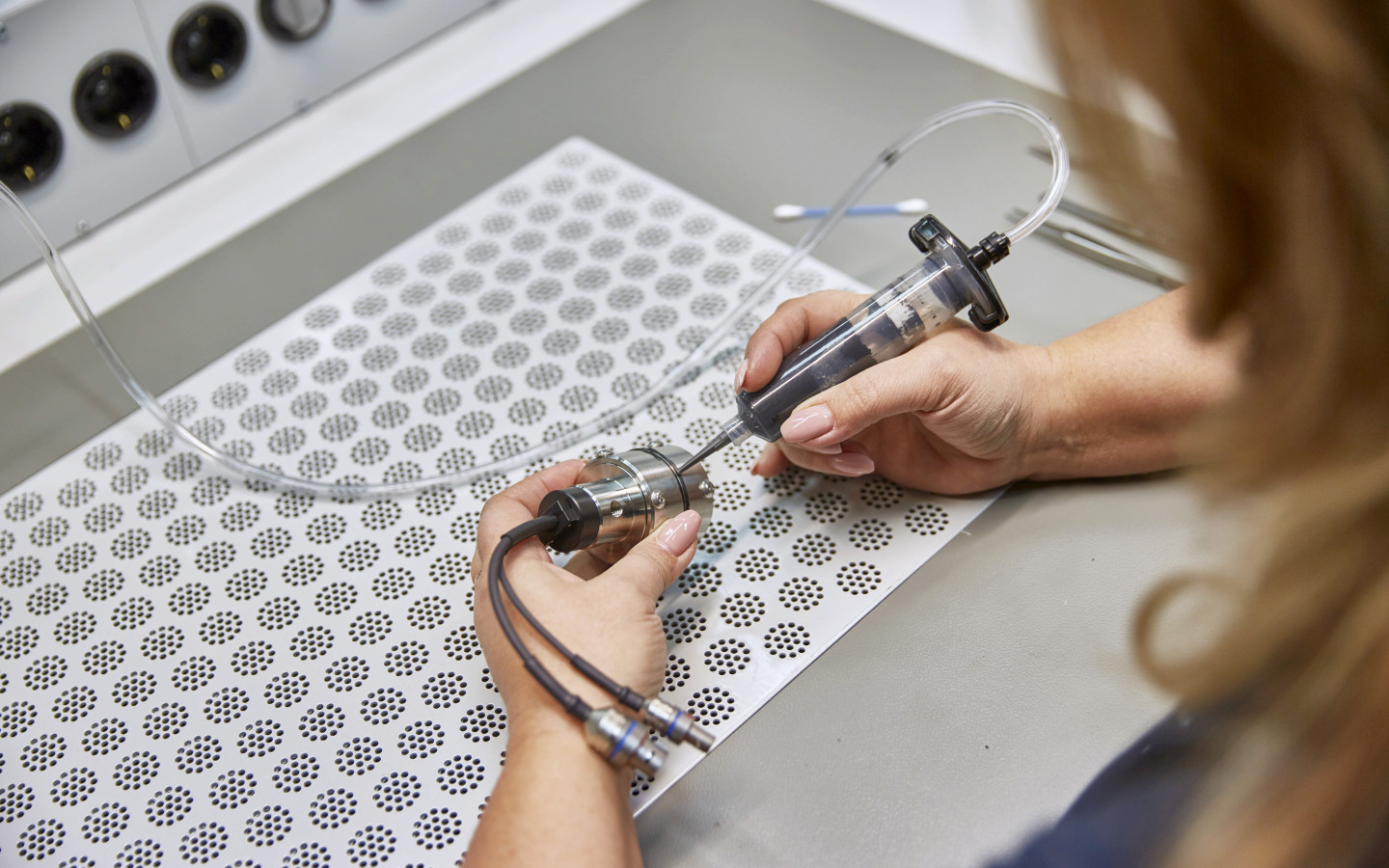

The Swiss high-tech company Kistler has merged and reorganised two of its German production sites for sensor technology in Sindelfingen. Kistler Instrumente GmbH has opted for ergonomic solutions from the workstation experts at Karl, Waldmann and Bimos to ensure that the new production facility is optimally equipped. Karl from Fahrenzhausen near Munich supplied and designed 100 ESD-compatible workstations for the production and service areas alone.

Efficiency and flexibility

1530 millimetres

The most important objectives when planning the new site in Sindelfingen were the efficient interior design of the building and the most flexible and standardised set-up of the workstations possible. "With the help of detailed model studies in digital and haptic form, we optimised the material flow, process development and transport routes to determine the layout of the workbenches," says André Hanich, Project Manager Lean & QA and involved in the planning of the site. The spatial arrangement of logistics, production, calibration laboratory and workshops now enables optimised short distances and a more efficient workflow. Another criterion was the flexible use of the desks. "As the majority of our employees work in different areas, the workstations must allow for flexible changes at any time," explains Hanich. In contrast to the old locations, each employee no longer has their own workstation in Sindelfingen, but can theoretically take a seat at any work table, depending on the work step they are carrying out. In collaboration with Karl, two standard dimensions were decided upon in the production hall: the table width for production workstations is 1530 millimetres. "This means that the table width corresponds to the ergonomically defined range that can be reached with outstretched arms without changing position."

"The interaction between microscope and lighting is very important"

Ergonomic all round

"The interaction between the microscope and the lighting is very important," explains Eberhard Bauer, Head of Production Centre at Kistler. "If the incidence of light changes when looking up, the pupil opens and closes every time. This leads to rapid signs of fatigue." The light intensity of the selected Waldmann lights can be adapted to the microscope lighting in such a way that this strain on the eyes is avoided. An ergonomic workstation also requires the right chair. Kistler opted for chairs from Bimos, which can be customised to the individual needs of each employee. "The entire team received training from a Bimos employee on how to adjust the chairs. After that, everyone agreed that the chairs were ideal for the requirements in our production hall." Of course, standing still is a step backwards. So it's good that the position of the workstations in the building is not fixed, but can be reconfigured at any time. "With the modular Karl programme, we can react quickly to future requirements and growth."

Downloads

pdf, 287 KB

DE

DE